the CAp®

The brand „the CAp®” belongs to our 100% Hungarian, family-owned business, established in 2004. The company’s original profile is the production of stainless-steel tanks and accessories, mainly for wineries.

As a family business, we have always placed particular emphasis on communication with our customers; we think of them not only as customers, but more as partners.

Our partners are the ones who help us to get an accurate idea of what a winery needs and what aspects to take into account when developing our products. They also help us to identify what changes can make the use of certain products more efficient or even more convenient. This joint collaboration highlights the segments where our partners sometimes

forced to run the extra mile in terms of raw material use, development or logistics, and how we as a supply partner can contribute to these areas.

One of these segments is the increasingly important screw cap market. A significant percentage of Hungarian wineries are forced to rely on foreign manufacturers which poses challenges for them in terms of both flexibility and logistics.

We found the opportunity in this and decided to create our own screw cap to provide quality and easy-to-plan logistical service to our existing and prospective partners; all in Hungary.

Thanks to this, „the CAp®” was born in 2022.

Our screw cap name is not only a new product for us, but also a family symbol.

The name was chosen to convey the strength and reliability that the memory of the founder of the family business – our father – Antal Csúzi, deserves. By highlighting the initials of his name, under the brand „the CAp®”, each and every screw cap is part of our ambition to build a mutually satisfying, forward-looking and ever-evolving business relationship with our partners.

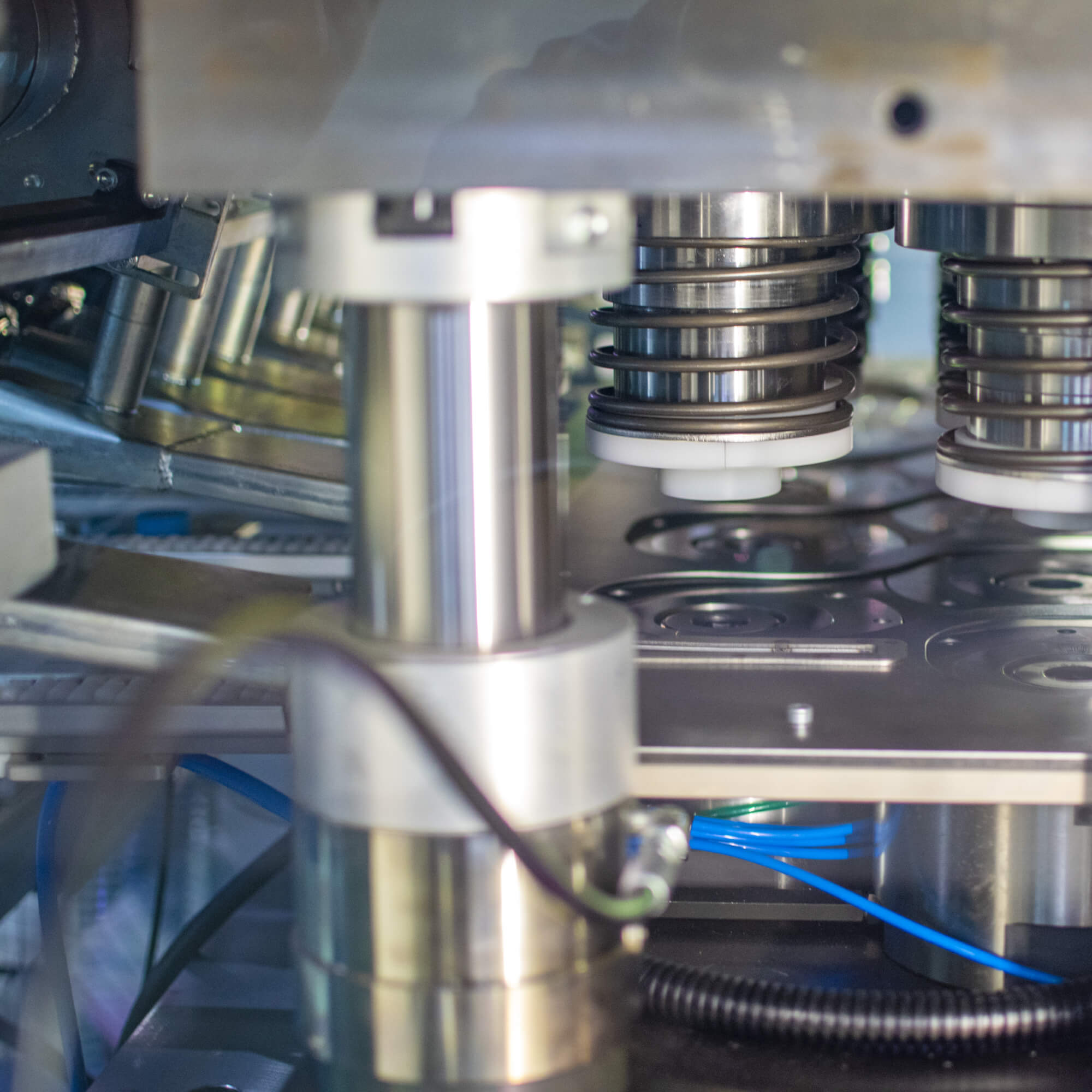

We rely on the motto „Best or Nothing” when it comes to sourcing the tools needed to achieve this. With our Italian production line BortolinKemo, capable of producing 45,000 screw caps per hour, our Swiss decorating machine Madag (Packsys Global AG) with a real foiling and embossing capacity of 6,000 pcs/hour and the excellent screw cap liners from German Meyer Seals®, we want to satisfy our customers’ needs at the top level of the market segment.

Technology

„the CAp®” screw cap is made in a standard 30x60mm size, making it fully compatible with the screw cap bottles used in the wine industry. We have taken great care in the design of the mould and have eliminated all known defects, striving for perfection in terms of both manufacture and usability.

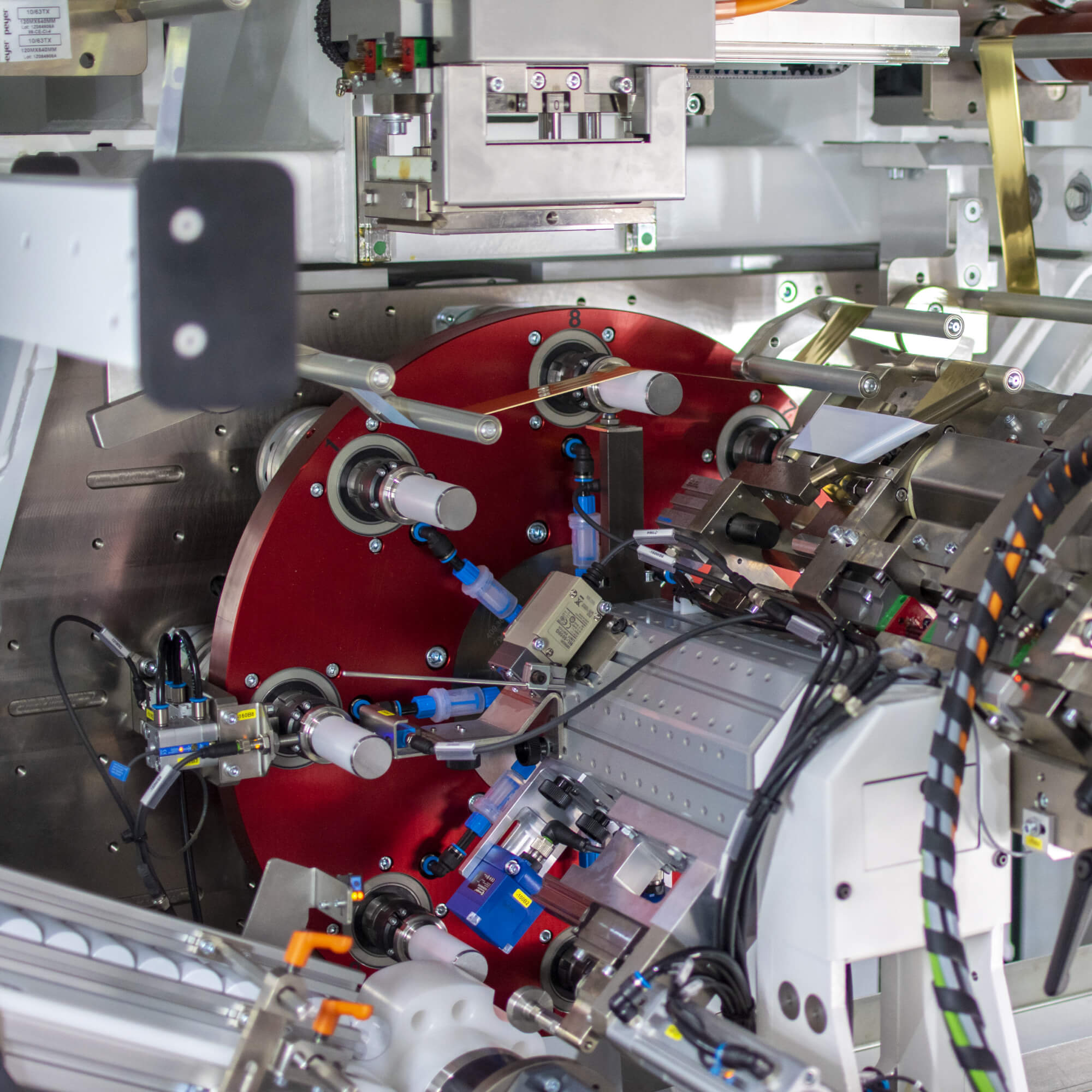

Our aim was to be able to lithograph the screw caps ourselves, so that we could offer our partners the widest possible range of decorative options in the most flexible way. We were looking for a solution that would allow us to decorate both the sides and the top of the screw caps at the same time, while embossing would be done in the same work step.

The choice could only be the one of the most experienced and reliable companies in the production of hot foil machines, Madag (Packsys Global AG) from Switzerland. To select the most suitable machine – in addition to the main criteria mentioned above – full automation and the highest production reliability available were the key features that allow us to confidently place our technology at the service of our partners.

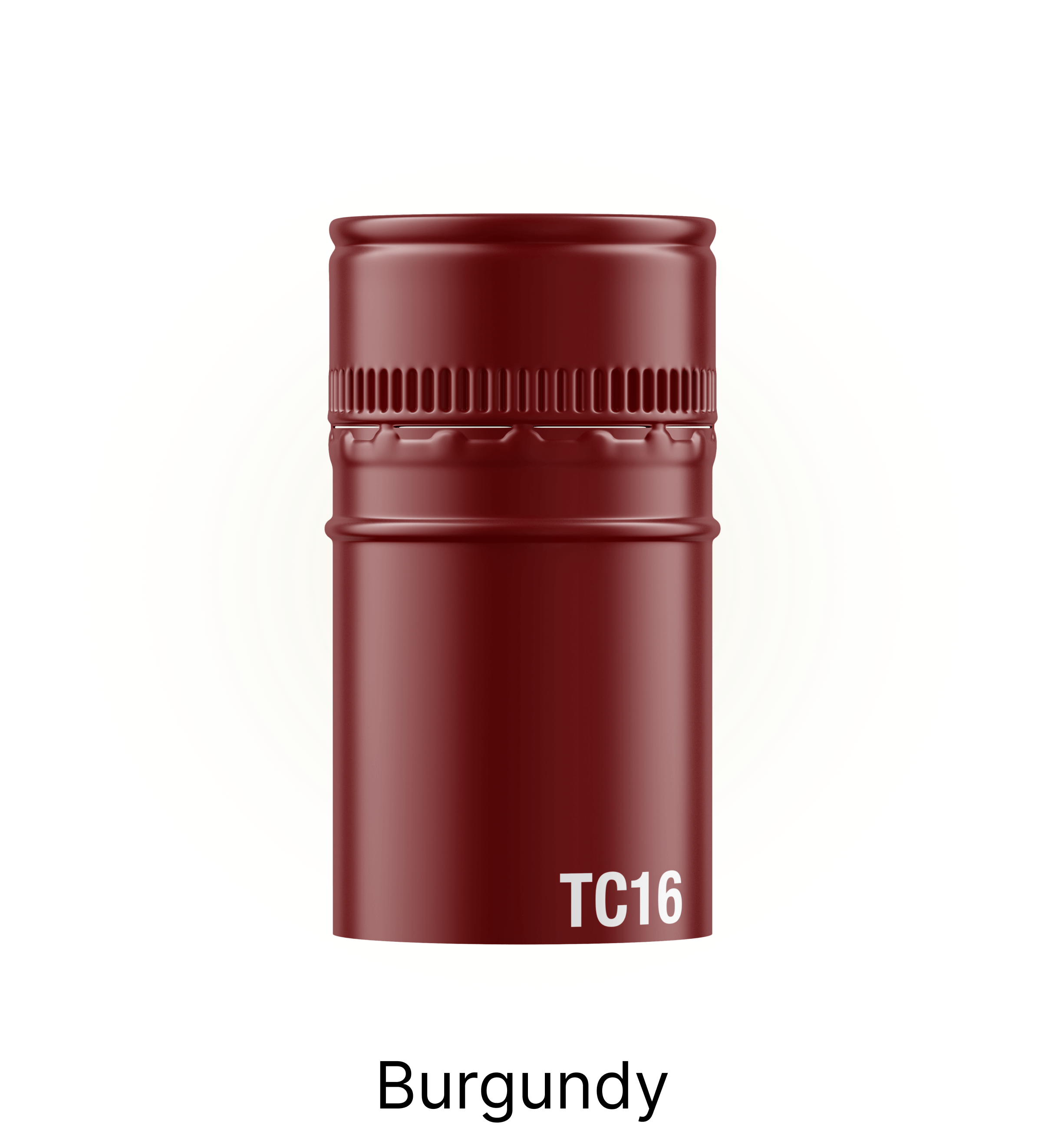

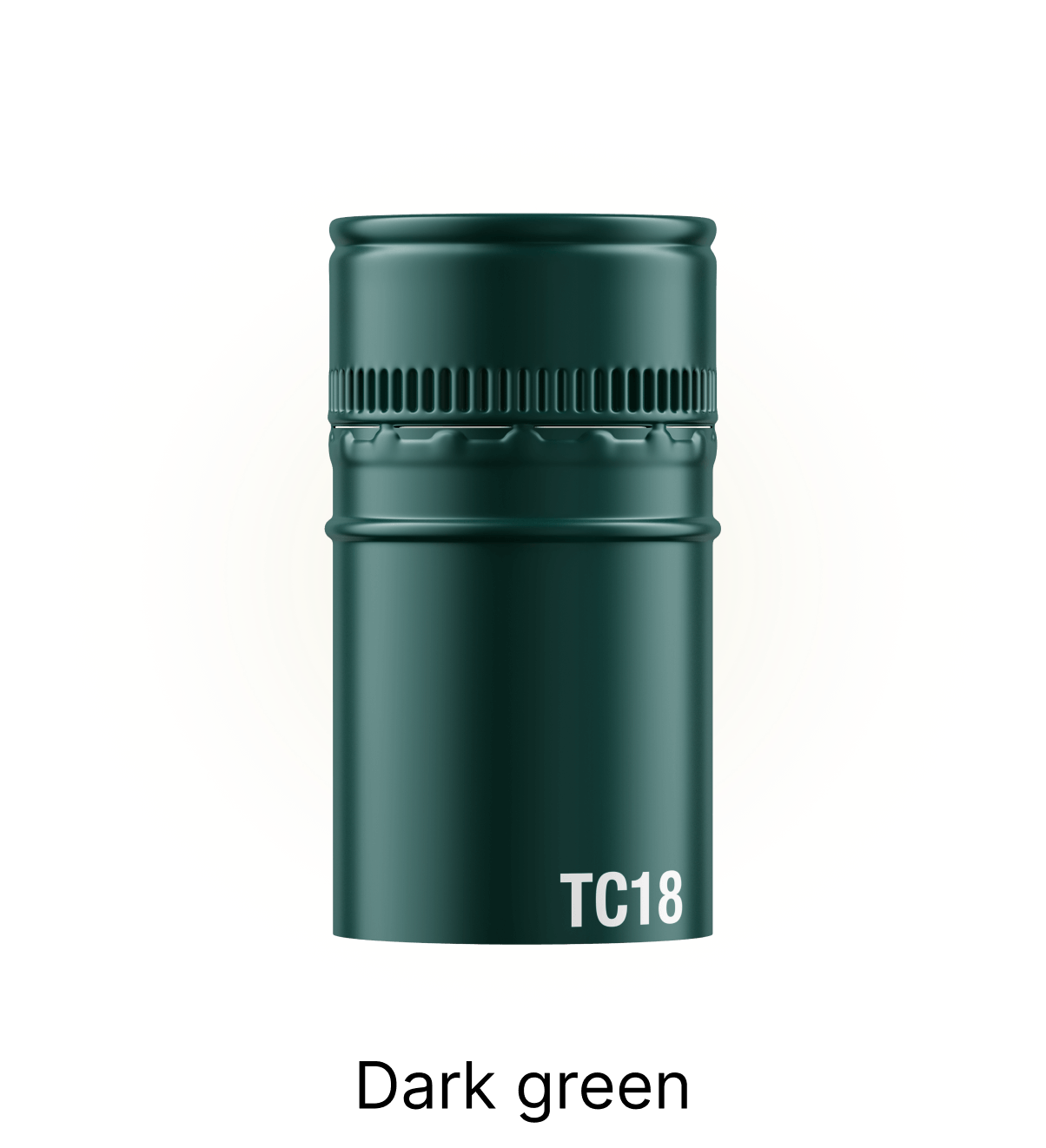

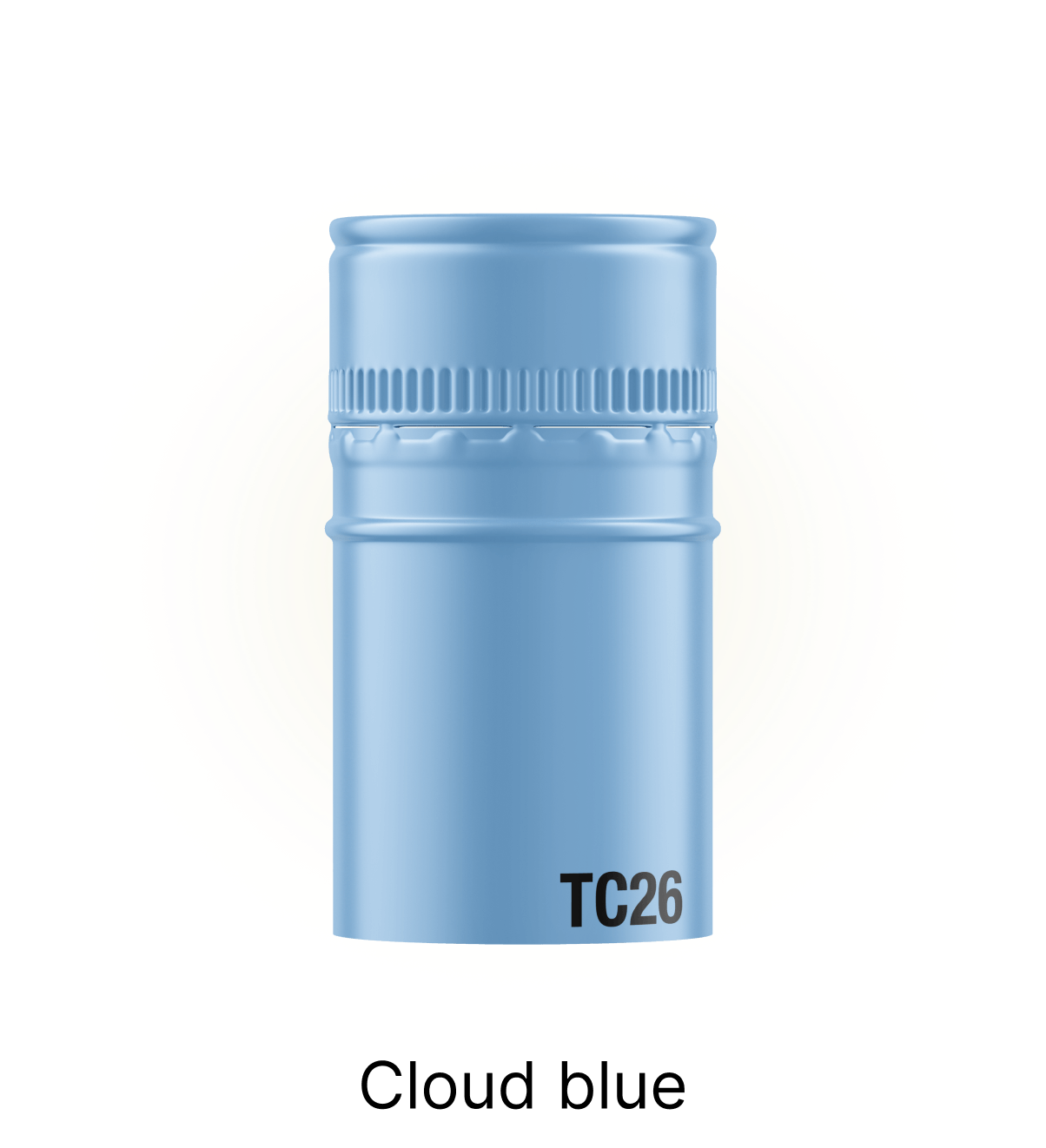

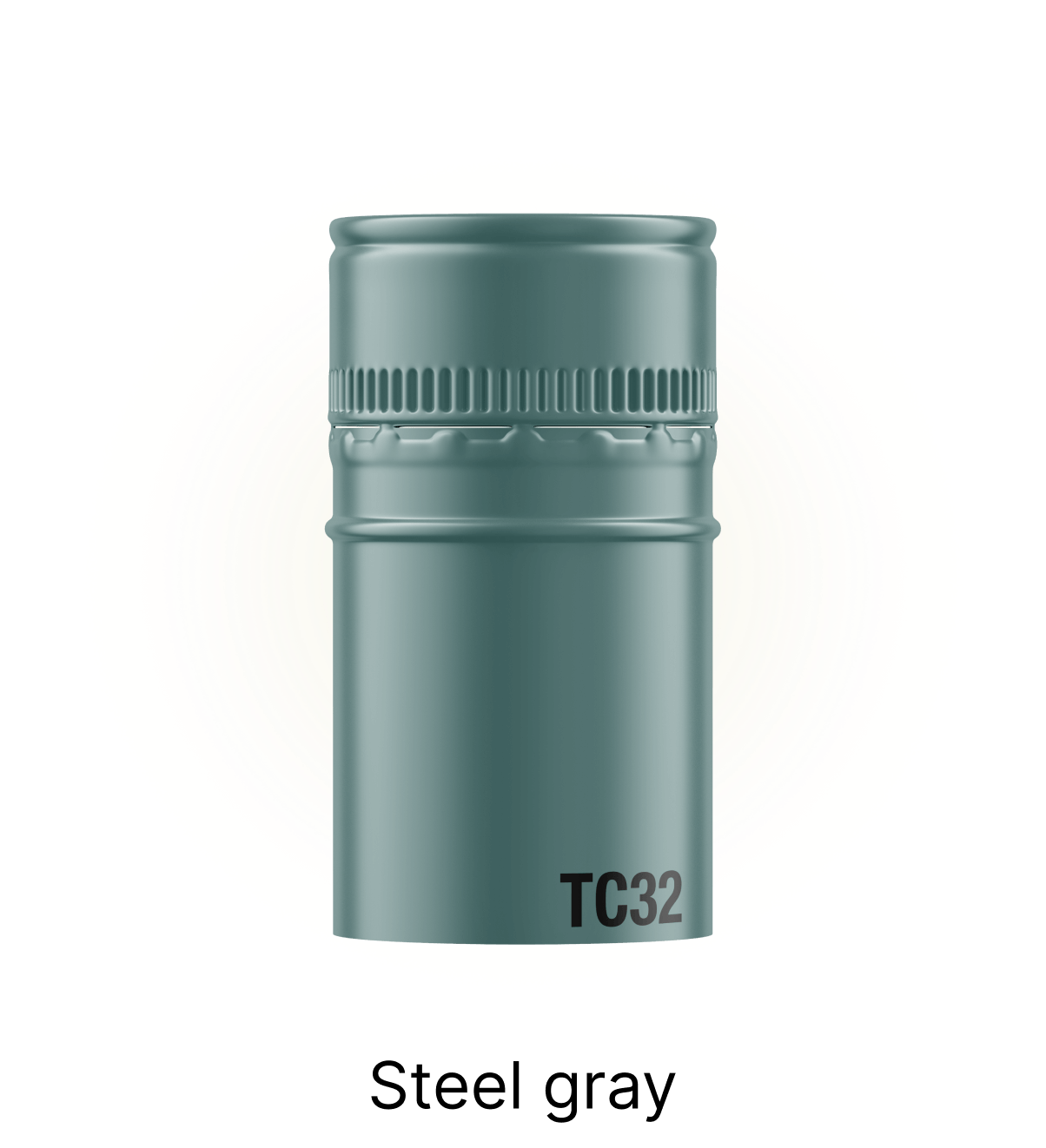

Screwcap

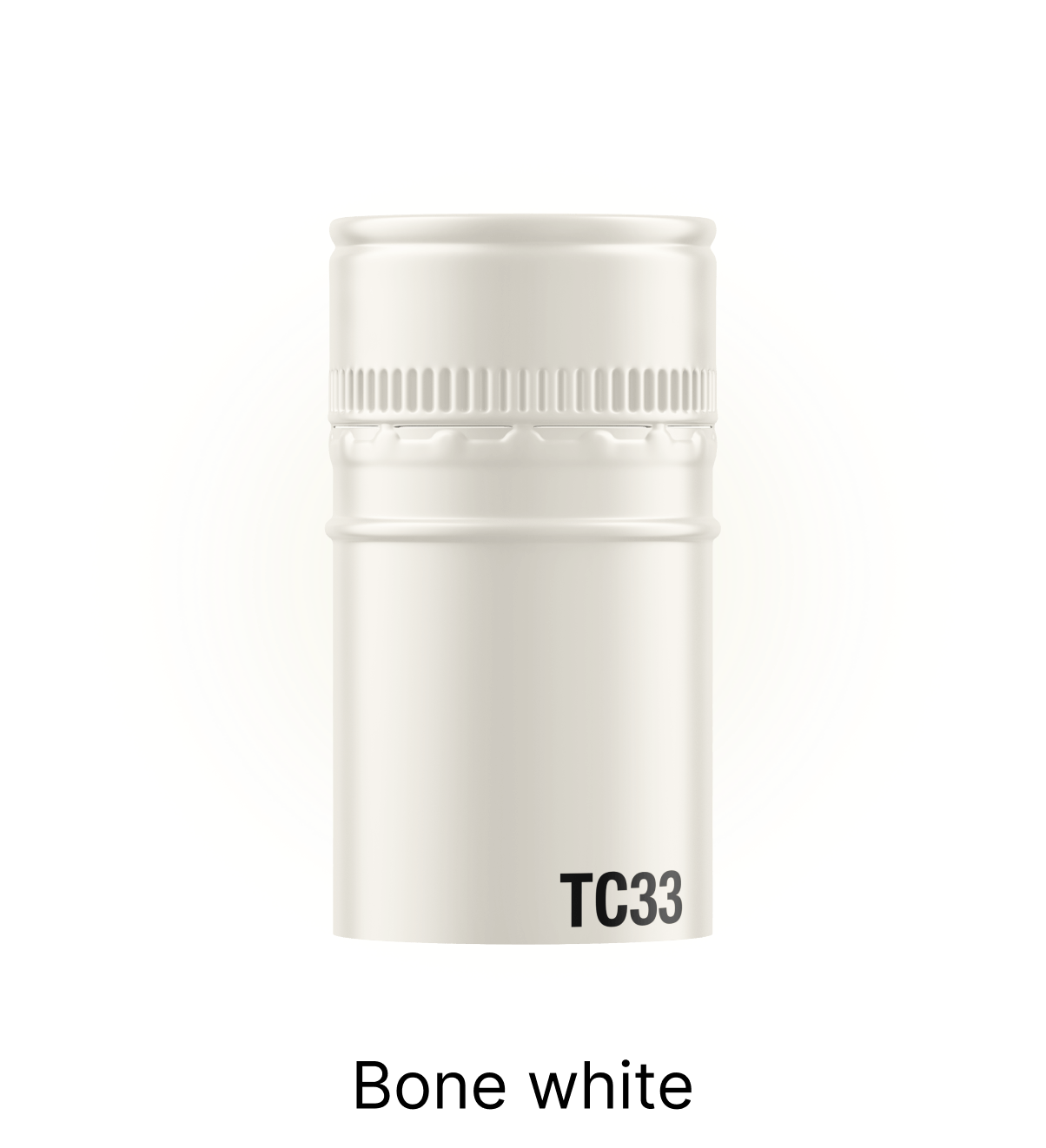

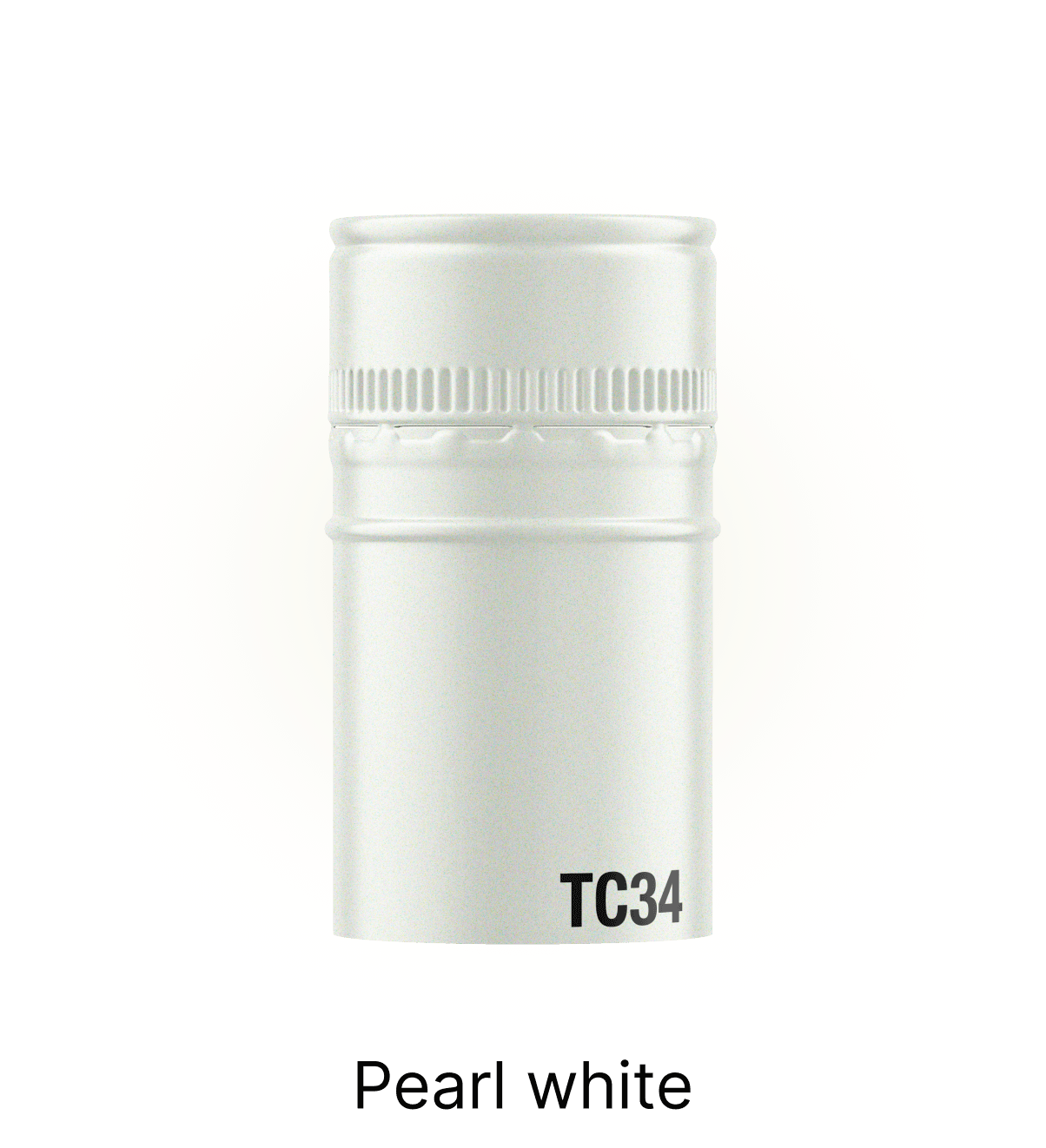

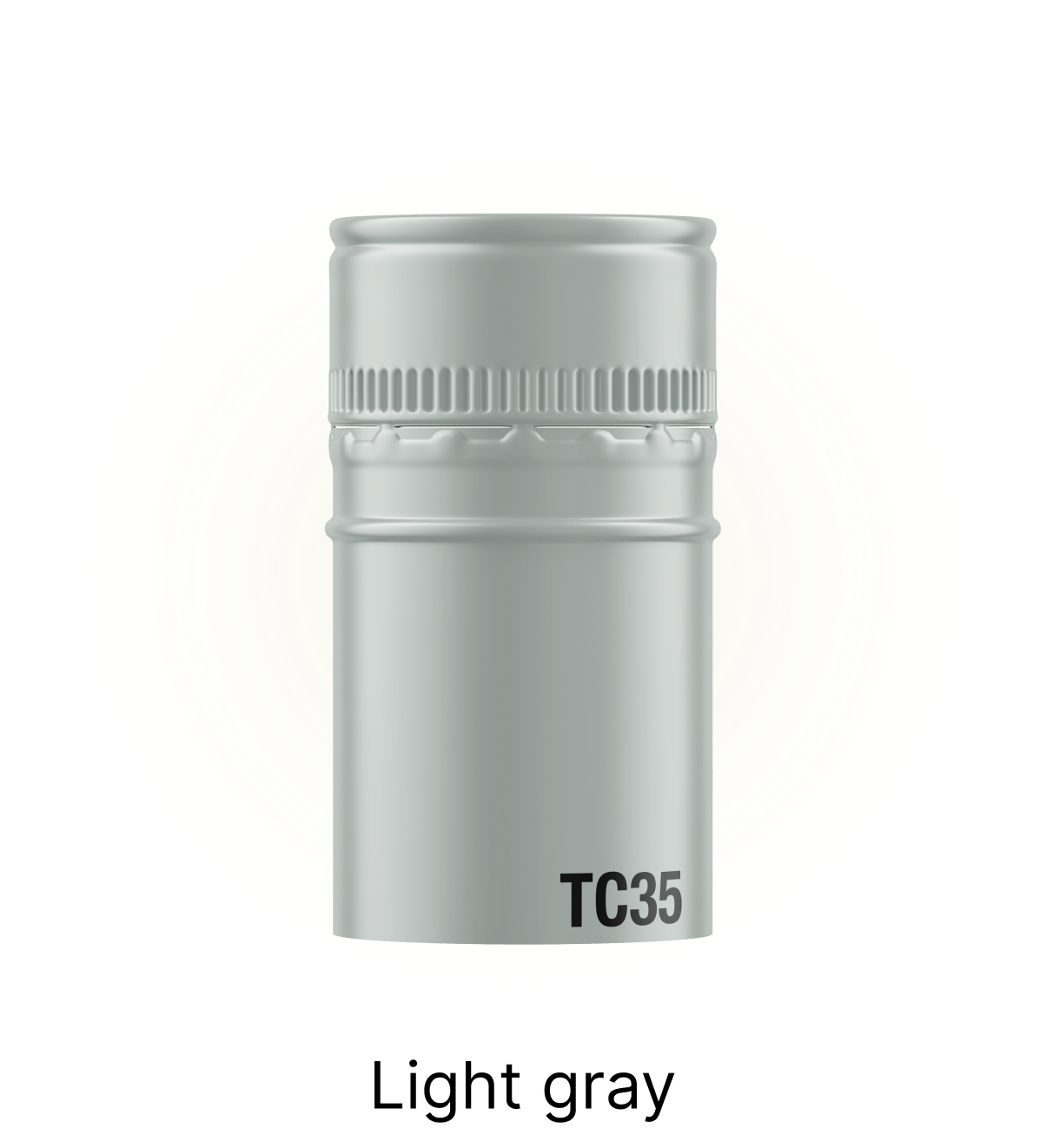

Our standard colours are constantly adjusted to the needs of our customers.

Sealing

After discussions with the machine manufacturers and suppliers, we decided to introduce the new ALKOvin™ active, in addition to the 2 basic screw cap liners (ALKOvin™ tin and ALKOvin™ Saranex®), which are already well known in the winery, in close cooperation with the developer – Meyer Seals®. Recognising the advantages of the new liner, Australian and New Zealand wineries have been using it for their reductive batches with maximum satisfaction since 2016.

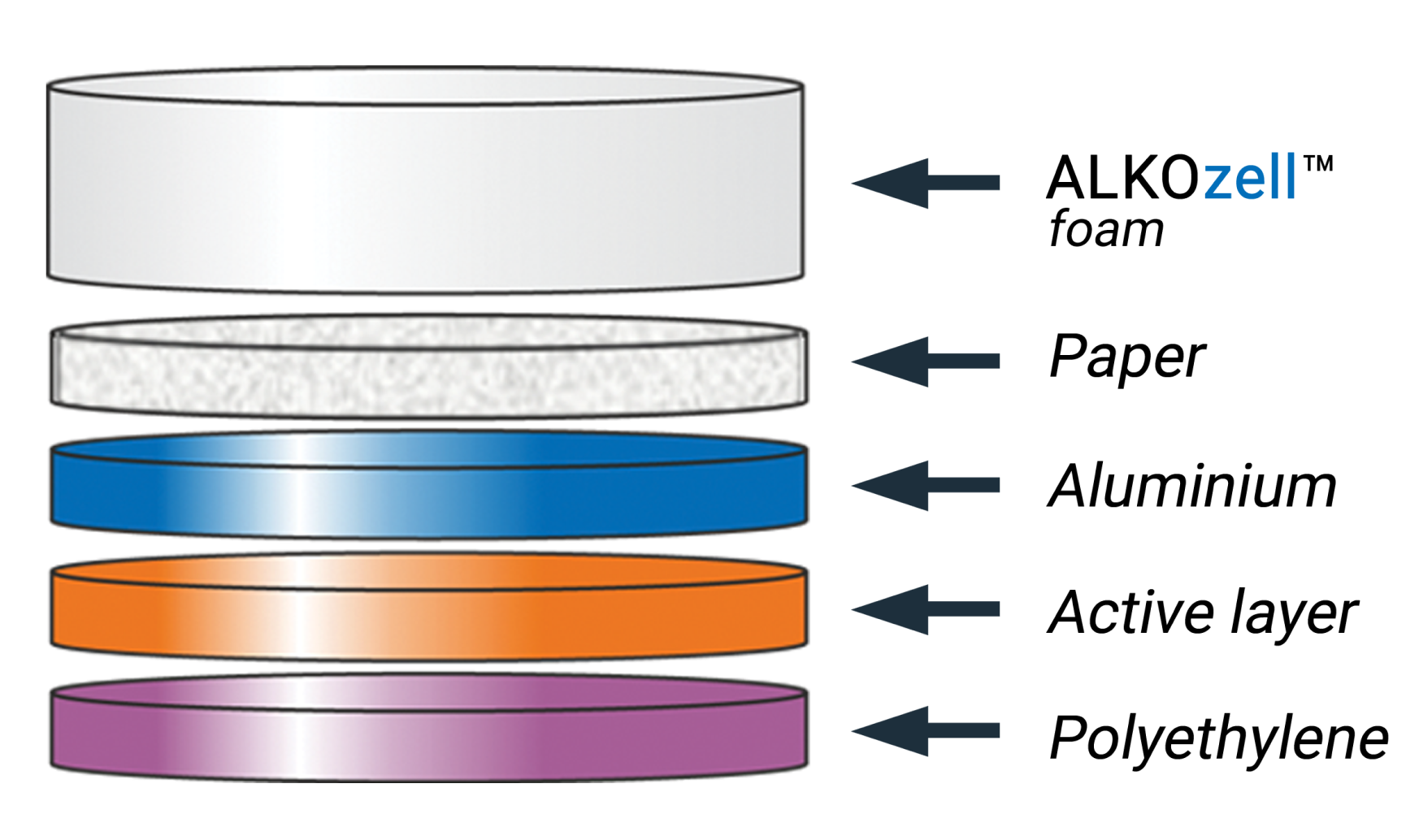

The new generation of screw cap liners – ALKOvin™ active.

A new innovative development from Meyer Seals®, providing exceptional protection against both oxidation and reductive ageing. In addition, it controls the reductive flavour characteristics after bottling, providing all the benefits of the classic „Tin/Saran” liner:

- Reduces and prevents the formation of volatile sulphur compounds (VSCs), which are responsible for taste defects after bottling.

- Does not influence the typical varietal aromas, found for example in Sauvignon and in Scheurebe.

- Does not have any negative impact on wines which are not prone to reductive notes

- Offers excellent oxygen barrier performance (OTR ≈ 0.0 mg O2/yr)

- Is free of PVDC and PVC

- Is a liner compatible with all wine screw caps

- Has been tested by the renowned “Australian Wine Research Institute” (AWRI)/li>

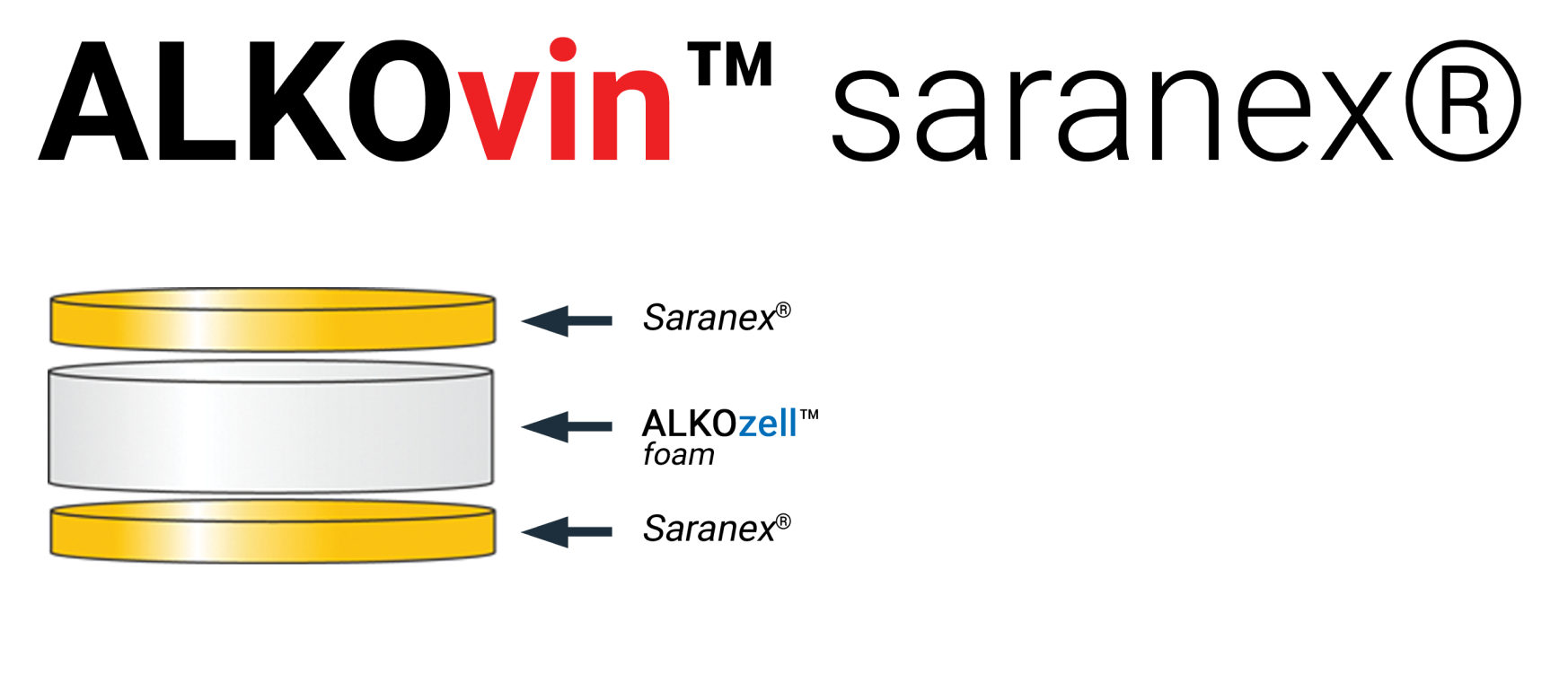

The most popular screw cap liner among winemakers/wineries due to its known advantages. ALKOvin™ saranex® is ideal for sealing all wines that require controlled oxygen ingress.

Oxygen permeability: 1,48 ± 0,04 [cm3/m2. 24 hours. 0,1 MPa]*

*Indicative value only

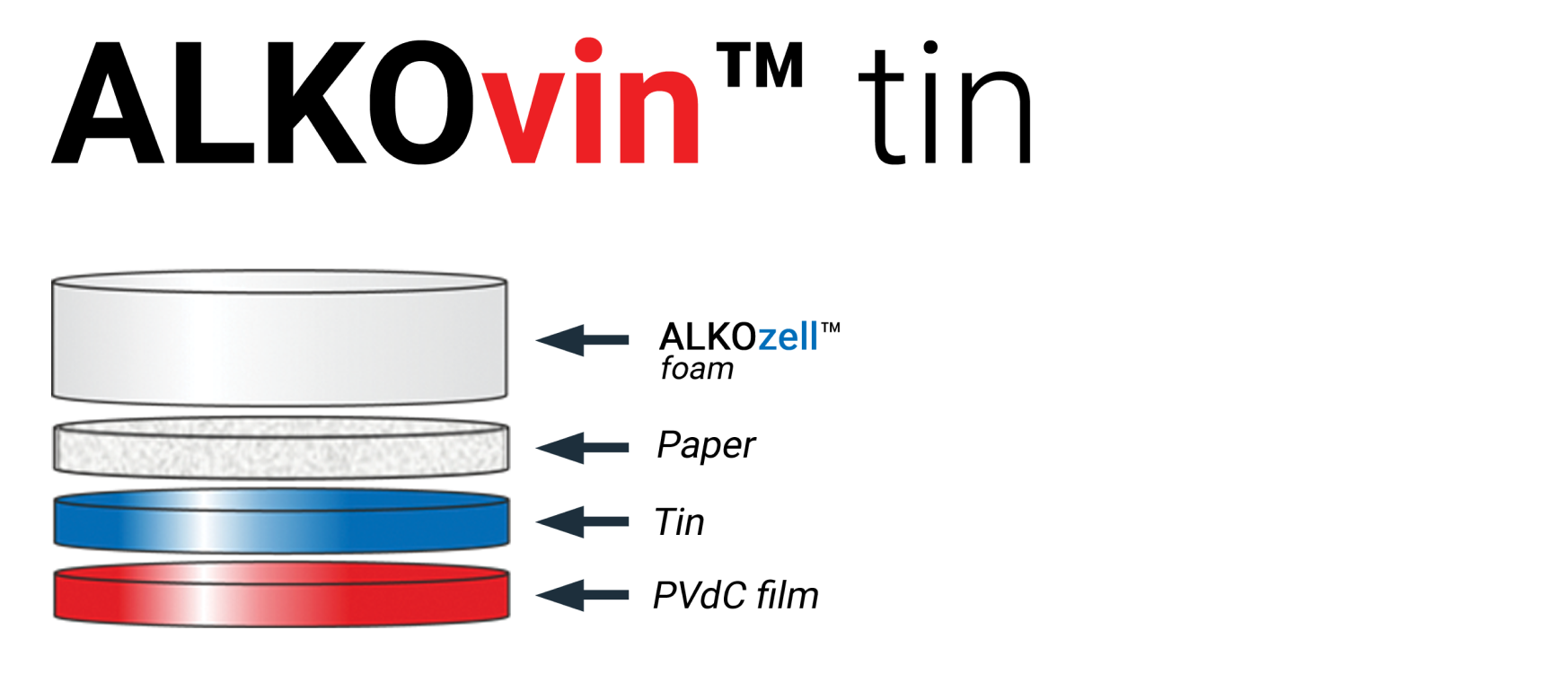

In this screw cap liner, the combination of layers provides the highest level of oxygen barrier to protect the contents of the bottle. ALKOvin™ tin is perfect for all wines that need to be stored for extended periods of time.

Oxygen permeability: ~ 0 [cm3/m2. 24 hours. 0,1 MPa]*

*Indicative value only

Contact us

Gabor Bukta